Raw materials

The porcelain paste used at the Meissen Porcelain Manufactory consists primarily of kaolin plussfeldspar and quartz.

Kaolin, also known as china clay or porcelain earth, was formed approx. 100 million years ago. The paste used by the Meissen Porcelain Manufactory contains a 65% fraction of kaolin. Kaolin makes porcelain products firm and resilient. Owing to the high proportion of kaolin used, Meissen refers to its porcelain as being “hard-paste”.

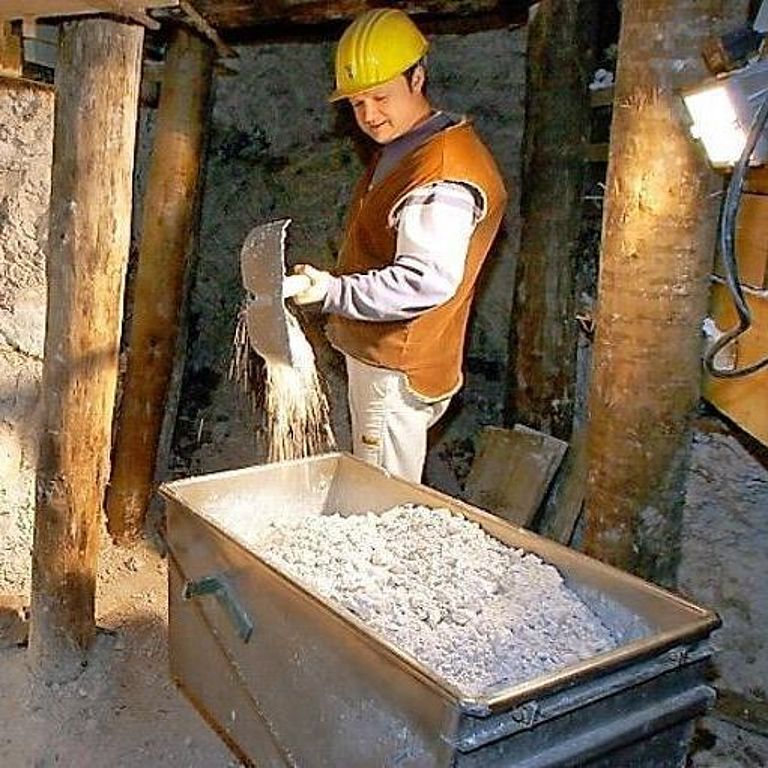

Our kaolin comes from Seilitz, probably the smallest mine in Europe. Roughly 150 tonnes of the raw material have been extracted there annually ever since 1764. Kaolin is what makes porcelains white. It doesn’t melt during firing either, so items leave the kiln the same shape as when they went in.

Feldspar and quartz act as fluxing agents (knitting the kaolin together as it were). Quartz enhances the body’s purity and transparency, whilst feldspar reduces the firing temperature.